Transparent conductive oxides (TCOs) are used in various optoelectronic technologies with the most widely commercialized TCOs consisting of n-type semiconductor materials. Their counterpart, the p-type TCOs, are being actively pursued by the scientific community with a higher mobility and a lower cost. The latter objective is more important in photovoltaic and light-emitting applications, where high mobility p-type TCOs are not required but low-cost solution-processed materials are essential to enable large-area manufacturing on flexible substrates. This recent paper published in ACS Applied Materials & Interfaces (subscription required) details the work of University of Texas at Dallas and University of Washington researchers developing such low-cost optoelectronic products.

Transparent conductive oxides (TCOs) are used in various optoelectronic technologies with the most widely commercialized TCOs consisting of n-type semiconductor materials. Their counterpart, the p-type TCOs, are being actively pursued by the scientific community with a higher mobility and a lower cost. The latter objective is more important in photovoltaic and light-emitting applications, where high mobility p-type TCOs are not required but low-cost solution-processed materials are essential to enable large-area manufacturing on flexible substrates. This recent paper published in ACS Applied Materials & Interfaces (subscription required) details the work of University of Texas at Dallas and University of Washington researchers developing such low-cost optoelectronic products.

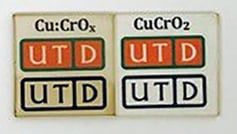

Jian Wang, formerly of UT-Dallas and now with the Clean Energy Institute at UW, was lead author of the paper, which reports on a solution synthesis method to produce two p-type TCO thin films. Instead of the high-vacuum or high-temperature sol-gel type processing techniques commonly used for p-type thin-film fabrication, the researchers used a lower-temperature (180 °C) “combustion chemistry” approach to synthesize copper chromium oxide and copper doped chromium oxide films. In the paper, they discuss the annealing process for the two films, then describe how they characterized the electronic, optical, and transport properties of the two materials, with a Lake Shore Model 8404 Hall system specifically used to verify that materials are p-type. The 8404 AC field option was used for these TCOs. The measured mobilities were 0.23 cm2/Vs and 0.008 cm2/Vs.

Jian Wang, formerly of UT-Dallas and now with the Clean Energy Institute at UW, was lead author of the paper, which reports on a solution synthesis method to produce two p-type TCO thin films. Instead of the high-vacuum or high-temperature sol-gel type processing techniques commonly used for p-type thin-film fabrication, the researchers used a lower-temperature (180 °C) “combustion chemistry” approach to synthesize copper chromium oxide and copper doped chromium oxide films. In the paper, they discuss the annealing process for the two films, then describe how they characterized the electronic, optical, and transport properties of the two materials, with a Lake Shore Model 8404 Hall system specifically used to verify that materials are p-type. The 8404 AC field option was used for these TCOs. The measured mobilities were 0.23 cm2/Vs and 0.008 cm2/Vs.

For more on the topic of AC field Hall used for low-mobility research, download our new whitepaper. The paper begins by examining the DC and AC field Hall protocols then provides examples of AC field Hall used for analyzing micro-crystalline silicon, bismuth vanadate (BiVO4) metal oxides, and other materials.