A new paper detailing the work of Georgia Tech researchers developing wide-bandgap semiconductor devices references the use of our new FastHall™ measurement technology for validating conductivity type and carrier concentrations of samples grown using a metal modulated epitaxy (MME) technique.

A new paper detailing the work of Georgia Tech researchers developing wide-bandgap semiconductor devices references the use of our new FastHall™ measurement technology for validating conductivity type and carrier concentrations of samples grown using a metal modulated epitaxy (MME) technique.

The paper, included in this month’s Advanced Materials journal (subscription required) and co-authored by our own Jeff Lindemuth, describes investigations of MME-grown beryllium (Be) doped aluminum nitride (AIN) films that showed:

substantial p-type conductivity with hole concentrations in the range of 2.3 × 1015 – 3.1 × 1018 cm-3 at room temperature. While others have achieved sizable carrier concentrations near surfaces via carbon doping or Si implantation, this is the only known demonstration of substantial bulk p-type doping in AlN and is a nearly 1000 times higher carrier concentration than the best previously demonstrated bulk electron concentrations in AlN.

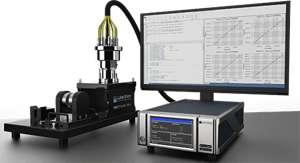

This study, led by Professor W. Alan Doolittle from the School of Electrical and Computer Engineering, is part of work toward the potential development of AIN-based high-power electronics and deep ultraviolet (DUV) devices. Our MeasureReady™ FastHall Station, a fully integrated tabletop system for performing fast, highly precise Hall effect measurements, aided the team in their research. Specifically, it was used for four-point probe measurements in a van der Pauw configuration for determining I–V characteristics of electrical contacts on the AlN:Be film samples.

This study, led by Professor W. Alan Doolittle from the School of Electrical and Computer Engineering, is part of work toward the potential development of AIN-based high-power electronics and deep ultraviolet (DUV) devices. Our MeasureReady™ FastHall Station, a fully integrated tabletop system for performing fast, highly precise Hall effect measurements, aided the team in their research. Specifically, it was used for four-point probe measurements in a van der Pauw configuration for determining I–V characteristics of electrical contacts on the AlN:Be film samples.

In addition, high-temperature DC and Hall measurements of the samples were performed at Lake Shore Cryotronics using our MeasureReady M91 FastHall measurement controller on our MeasureReady™ MCS-EMP system with a Model 336 temperature controller (MCS-EMP-4T-V) and a high temperature oven (EMP-OVEN) option.