Instrumentation performance is paramount to ensuring accurate characterization of electronic materials and devices; however, electrical measurement equipment performance varies widely. One often overlooked variable is the amount of noise that an instrument introduces.

Adding noise to a measurement has two obvious impacts:

- More data required—Increased noise means a larger number of data collections will be required to determine average response.

- Bias error—Because the noise spikes are all positive in orientation, the average response can have a bias error attributed to additional energy being introduced.

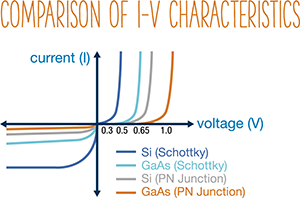

Consider a typical current-voltage (I-V) measurement for a diode. In the forward bias condition, the current initially increases very slowly until the bias voltage approaches the “forward voltage.” At that point, the current dramatically increases in a non-linear fashion.

Consider a typical current-voltage (I-V) measurement for a diode. In the forward bias condition, the current initially increases very slowly until the bias voltage approaches the “forward voltage.” At that point, the current dramatically increases in a non-linear fashion.

To characterize the forward voltage of a diode, it is common to use a current source and voltage meter to plot the I-V curve. Therefore, as the forward voltage is approached, the positive noise spikes can act to prematurely push the diode into its “on” region, causing a small corruption of the I-V curve.

Choosing an instrument that is proven to be low noise can help reduce this error and save time when conducting measurements. Lake Shore’s soon-to-be-released MeasureReady™ 155 precision I/V source is one example.

To refresh your memory on additional measurement mistakes to avoid, download our free 5 Measurement Pitfalls whitepaper.