Last November, we discussed briefly how a Lake Shore probe station can be used with a Radiant Technologies test system to characterize piezoelectric (PZT) device performance at 6 K temperature. At that time, our blog post mainly focused on the ability to rapidly characterize the device’s ferroelectric properties, and to illustrate, we included a video showing how a PZT capacitor’s membrane physically moves when it receives voltage while being probed in the Lake Shore CRX-EM-HF probe station.

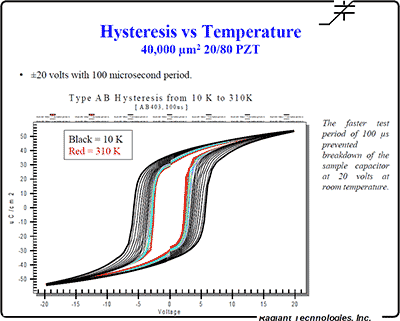

More recently, Radiant Technologies has posted a presentation on its website that details a similar ferroelectric thin film measurement application — this one done over variable temperatures using our CRX-4K probe station with temperature-compensated probes. It shows the results of using our probe station and its Model 336 temperature controller with a Radiant Technologies Precision test system to make physical property measurements everywhere from 5 K up to 310 K. These included measurements of 20/80 PZT and 3/20/80 PNZT thin ferroelectric film capacitors. Understanding the PZT and PNZT mechanisms as a function of temperature can help researchers in their efforts to more effectively thermally engineer ferroelectric components, and in this variable temperature measurement application, conclusions regarding phase boundary, coercive voltages change, switching speed, and device leakage could be made.

Also in this application, Lake Shore and Radiant Technologies gained a better understanding of workflow efficiencies possible in a Model CRX-4K/Precision test system setup — efficiencies that allow making multiple temperature measurements a much less tedious process. The station’s controller was used to automate characterization over a wide temperature range, with the system ramping between preprogrammed temperature setpoints for different measurement types. This way, it is possible to “measure and plot hysteresis, remanent polarization, leakage, and small signal capacitance over a large temperature range in a single pass on a single sample,” as noted in the application presentation.

So instead of having to endure a long, drawn-out process of taking a number of measurements at every temperature point, a researcher can program a series of tests and walk away to spend time on other things, like growing materials in a clean room.

As with this blog post about a probe station/Keithley analyzer application for automating measurement tasks, this is just one more way that Lake Shore is collaborating with other companies to offer solutions that enable more efficient, more productive work in the lab.