It’s a question we get often from customers who are evaluating their options for sample cooling: What are the main differences between pulse tube cryocoolers (PT) and Gifford-McMahon cryocoolers (GM)?

To begin with, three differences have to do with price, intended orientation, and maintenance interval:

- GM cryocoolers are generally less expensive than PT cryocoolers of similar cooling power.

- PT cryocoolers only function properly when they are operated in a purely vertical orientation with the 2nd stage pointing down. By contrast, GM cryocoolers can operate in any orientation; and even though cooling power is slightly reduced when the cold head is not operated vertically, the base temperature is normally unaffected.

- Most GM cryocoolers require scheduled maintenance every 10,000 operating hours, compared with 20,000 hours for PT cryocoolers.

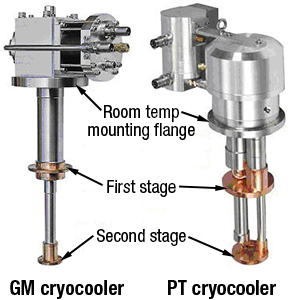

But there’s also a fourth major difference, which has to do with vibration levels. Both GM and PT cryocoolers are mechanical refrigerators that produce vibrations, both at the cold head’s room temperature mounting flange (which provides the interface for a vacuum shroud or vacuum chamber) and at the 2nd stage (where the sample being cooled is typically mounted).

But there’s also a fourth major difference, which has to do with vibration levels. Both GM and PT cryocoolers are mechanical refrigerators that produce vibrations, both at the cold head’s room temperature mounting flange (which provides the interface for a vacuum shroud or vacuum chamber) and at the 2nd stage (where the sample being cooled is typically mounted).

Which type of cryocooler to choose depends on the tolerable levels of vibration in your application or experiment and a couple of other factors:

A PT system is often a better choice if…

- Vibrations at the sample must be less than 20 µm.

- Vibrations from the cold head need to be isolated from other equipment that interfaces with the cryostat.

A GM system may be a better choice if…

- Vibrations on the order of 20 µm at the sample are acceptable.

- The cryostat will not be rigidly mounted to any equipment that is sensitive to mechanical vibrations.

- A base temperature of 4 K or below is necessary but a PT system is beyond your budget limitations.

- The cold head will not be oriented vertically with the 2nd stage pointing down.

For more information about these differences and what contributes to vibration, see this longer article on Janis cryocooler technology.

Need a special cryocooler design for applications where vibrations must be less than 5 µm at the sample? Talk to one of our Janis engineers today.