As dilution refrigerator (DR) designs enable temperatures that edge ever closer to absolute zero, the ability to accurately achieve and measure base temperatures becomes an increasing challenge.

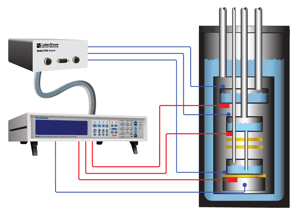

It turns out that temperature sensor and heater wiring can play a large part in whether a system can achieve its base temperature. These components will inherently be placed on the same stage of the DR and can be a convenient path for external heating sources to make their way into the sample stage.

In some cases, it is just the temperature sensor that experiences external heating. In this case, the temperature measurement shows a higher temperature than what the sample stage is actually operating at. In other cases, the external heating results in true heating of the sample stage, holding the DR back from achieving its true potential.

Our new application note “Model 372 AC Resistance Bridge Installation Best Practices for Measurement in a Dilution Refrigerator” reviews techniques for minimizing the impact of noise and other factors on DR temperature measurement accuracy. The note:

Our new application note “Model 372 AC Resistance Bridge Installation Best Practices for Measurement in a Dilution Refrigerator” reviews techniques for minimizing the impact of noise and other factors on DR temperature measurement accuracy. The note:

- Summarizes the industry-standard approach for ULT measurement

- Looks at obvious and no-so-obvious sources of sensor self-heating as well as noise sources and their effects

- Provides guidelines for protecting against external noise energies to ensure accurate readings

- Details steps for guarding against ground loops in measurement and heater circuits