With the U.S. Department of Energy’s recent announcement about new funding for solid-state lighting (SSL) R&D, we thought this would be a good time to summarize how Lake Shore systems and instruments can benefit research into light-emitting diode-related materials for both SSL and new display technologies. More R&D is being done in the field, with the need for higher-performing, energy-efficient technology driving much of it. In fact, the global LED lighting market alone is expected to reach $25.66 billion in 2015, according to a recent industry report.

With the U.S. Department of Energy’s recent announcement about new funding for solid-state lighting (SSL) R&D, we thought this would be a good time to summarize how Lake Shore systems and instruments can benefit research into light-emitting diode-related materials for both SSL and new display technologies. More R&D is being done in the field, with the need for higher-performing, energy-efficient technology driving much of it. In fact, the global LED lighting market alone is expected to reach $25.66 billion in 2015, according to a recent industry report.

Hall measurement systems

At the early stages of optoelectronics development involving electronic materials, researchers need not only to characterize material properties but also correlate them with electronic transport properties and determine carrier type and concentration of such carriers. Lake Shore offers systems that benefit early-stage solutions-based processing for both SSL and display-related research, including various transparent conducting oxides, such as tin oxide (SnO) materials.

Measuring for Hall effect is an essential tool for this type of work. The problem is some of these materials exhibit very low mobilities. For instance, a lot of research involves working with transparent zinc oxide (ZnO) materials on substrates, particularly for blue-emitting LEDs. ZnO materials, however, often have mobilities of less than 5 cm2/V s—which are rather difficult to measure with a standard DC field Hall effect measurement system. For this reason, the AC field Hall measurement methodology (available as an option on our 8400 Series HMS system) is quite useful when making mobility determinations. This method yields superior resolution in the Hall voltage measurement and, in turn, enables superior resolution in the mobility determination. Measuring mobilities to 0.001 cm2/V s is possible with AC field Hall measurement.

For more about the AC field Hall method of measurement, including example experiments that help explain AC measurements on low-mobility samples, read this application note.

Probe stations

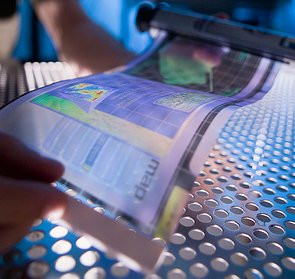

Researchers need to characterize material and test diode characteristics and behavior before taking the time to package into a full device. At this stage of R&D, a non-destructive test method is necessary. Cryogenic probe stations provide a solution, particularly if LED or OLED research requires a determination of the effects of temperature on carrier mobilities of thin-film substrates as well as device performance. Probe stations enable visualization and electrical interrogation of multiple wafer-level devices using micro-positionable probes, accelerating device characterization and fabrication efforts.

A probe station is an extremely flexible tool for a variety of device characterization applications. For example, cryogenic temperature-dependent I-V characteristics yield information about barrier alterations at transparent electrode/organic interfaces with different doping treatments—allowing a researcher to optimize hole injection from the electrode to the emitting layer in an organic LED. In both conventional and organic LEDs, a fiber optic probe can be used to collect light-current curves. These curves, performed as a function of temperature, can indicate trapping effects on carrier recombination. Finally, testing high operating temperatures in wide-bandgap LEDs can be achieved in Lake Shore probe stations with the addition of a high-temperature sample stage (30 K to 600 K).

A probe station is an extremely flexible tool for a variety of device characterization applications. For example, cryogenic temperature-dependent I-V characteristics yield information about barrier alterations at transparent electrode/organic interfaces with different doping treatments—allowing a researcher to optimize hole injection from the electrode to the emitting layer in an organic LED. In both conventional and organic LEDs, a fiber optic probe can be used to collect light-current curves. These curves, performed as a function of temperature, can indicate trapping effects on carrier recombination. Finally, testing high operating temperatures in wide-bandgap LEDs can be achieved in Lake Shore probe stations with the addition of a high-temperature sample stage (30 K to 600 K).

Multiple probe station options and configurations are available from Lake Shore. But, as standard, all probe stations feature a vacuum chamber in order to provide tight environment control for the sample under test. This minimizes sample condensation during cool-down and keeps surface flaws from occurring on any reactive organic test structures.

Programmable DC current source

This instrument can be a useful tool when conducting diode brightness testing during the design process—and can be a very affordable alternative to more expensive multi-function current sources. Light intensity relates to constant current, and an accurate, stable source of current is key to ensuring consistent operation of LED and OLED devices where the voltage drop across the device can be dependent upon temperature, magnetic field, and other parameters. With this low-noise, highly stable instrument, a user can program application-specific test currents and change current output automatically through a connected PC.

For more information

Please contact us at sales@lakeshore.com to discuss how we might aid you in your LED/OLED research.